Shyam Industries

-

Call us: 08:30 AM - 06:00 PM

+91 9450390105

-

E-mail us

info@shyamindustriess.com

Call us: 08:30 AM - 06:00 PM

+91 9450390105

E-mail us

info@shyamindustriess.com

The first step is to design the trailer based on the intended purpose, load capacity, dimensions, and regulatory requirements. This includes creating a detailed engineering drawing or 3D model.

Selecting appropriate materials for the trailer is crucial. Common materials include high-strength steel, aluminum, and occasionally fiberglass, depending on load capacity, weight, durability, and cost.

The fabrication process begins by cutting and shaping the chosen materials using industrial tools like plasma cutters, shears, or laser cutters to form structural components.

Skilled welders use techniques like arc welding, MIG, or TIG welding to join components, ensuring the trailer's structural integrity and durability.

Components are assembled, including chassis, frame, body panels, axles, suspension, braking system, and electrical wiring, following manufacturer specifications.

Sandblasting, priming, and painting protect the trailer from corrosion. Powder coating is often used for its durability and resistance to damage.

Additional features such as ramps, hydraulic systems, winches, and refrigeration units may be installed as per customer requirements.

Quality checks ensure compliance with industry standards, including structural integrity testing, brake testing, and electrical system checks.

The trailer is delivered to the customer with tracking details to monitor the manufacturing process and completion timeline.

Manufacturers provide documentation, warranties, and maintenance recommendations to ensure long-term reliability and safety.

These trailers have a load body with sides and no roof. They are often used for transporting large or oversized items, machinery, construction materials, and other loads that don't require enclosure.

The design and features of the load body are tailored to the specific needs of the cargo and the vehicle's intended use. It comes in 18-wheelers, 22-wheelers.

A truck is a heavy goods vehicle (HGV) with a tipper body on its rear. Commonly referred to as dump trucks, they are used to complete construction projects quickly and efficiently.

A tipper truck has a hydraulic system that allows it to tilt and unload cargo. They are frequently used for hauling loose materials like gravel, sand, and dirt.

A standardized, reusable metal or steel box designed for the storage and transportation of goods, facilitating efficient movement across various modes of transportation.

Tanker trucks transport bulk liquids, gases, and powders. They range from small fuel trucks to large semitrailers, offering versatile bulk transportation.

Light commercial vehicles (LCVs) weigh between 3.5 to 7 tons, offering a spacious cabin, good payload, and strong cargo body.

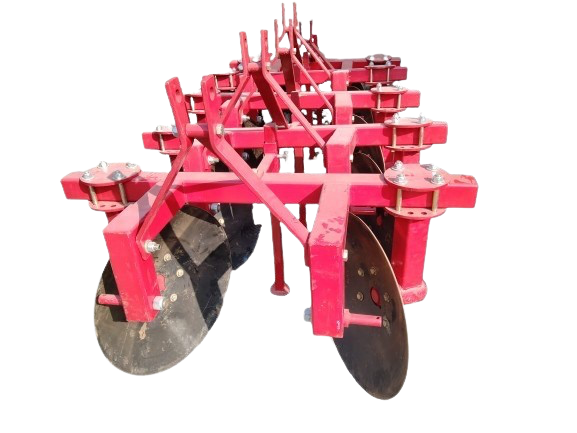

A Band Maker might be used for tasks like planting, harvesting, or processing crops efficiently. The Band Maker is an essential tool for agricultural tasks. It is designed to prepare fields for planting by creating neat rows for seed placement.

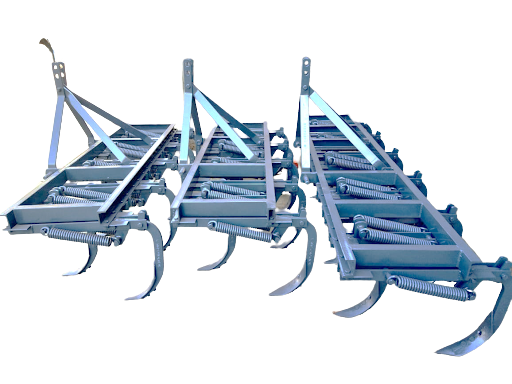

A cultivator is used for tilling soil and preparing it for planting crops. It helps improve soil aeration and moisture absorption, creating an ideal environment for healthy plant growth. Our cultivators are built to last and are suitable for various farming operations.

Whether you're dealing with flooded areas or need to clear excess moisture after heavy rains, the Mud Loader can operate in tough field conditions and ensure your land is ready for the next phase of planting or harvesting.